First they walked. Then they saw the light. Now small bio-robots have a new trick. It’s remote control.

According to researchers at the University of Illinois at Urbana-Champaign, Northwestern University and cooperating institutions, the hybrid “eBiobots” are the first to combine soft materials, living muscles and microelectronics. They described centimeter-scale biomachines in the journal Science Robotics.

“The integration of microelectronics enables the fusion of the worlds of biology and electronics, both of which have many unique advantages and could serve many future medical, sensing and environmental applications. We will be able to manufacture these electronic biobots and machines,” said the study.co-leader Rashid BashirProfessor of Illinois biotechnology, A faculty member of Carl Illinois Medical College, Grainger Institute of Technology.

Bashir’s group pioneered the development of biobots, small biological robots powered by mouse muscle tissue grown on 3D-printed soft polymer scaffolds. They demonstrated his walking biobot in 2012 and light-activated biobot in 2016. Photoactivation has given researchers some control, but practical applications have been limited by the question of how to deliver light pulses to biobots outside the laboratory.

The answer to that question came from a professor at Northwestern University John A. Rogersis a pioneer in flexible bioelectronics, whose team helped integrate miniature wireless microelectronics with battery-free micro LEDs. This allowed researchers to remotely control her eBiobot.

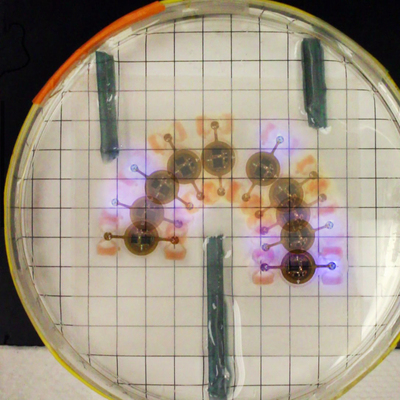

Remote control steering allows the eBiobot to avoid obstacles and maneuver as shown in this composite image of a bipedal robot traversing a maze.Image courtesy of Kim Young-deok

“This unusual combination of technology and biology opens up enormous opportunities to create artificial systems that are self-repairing, learning, evolving, communicating, and self-organizing. Rogers, Professor of Surgery and Director of the Quarry Simpson Institute for Bioelectronics, said:

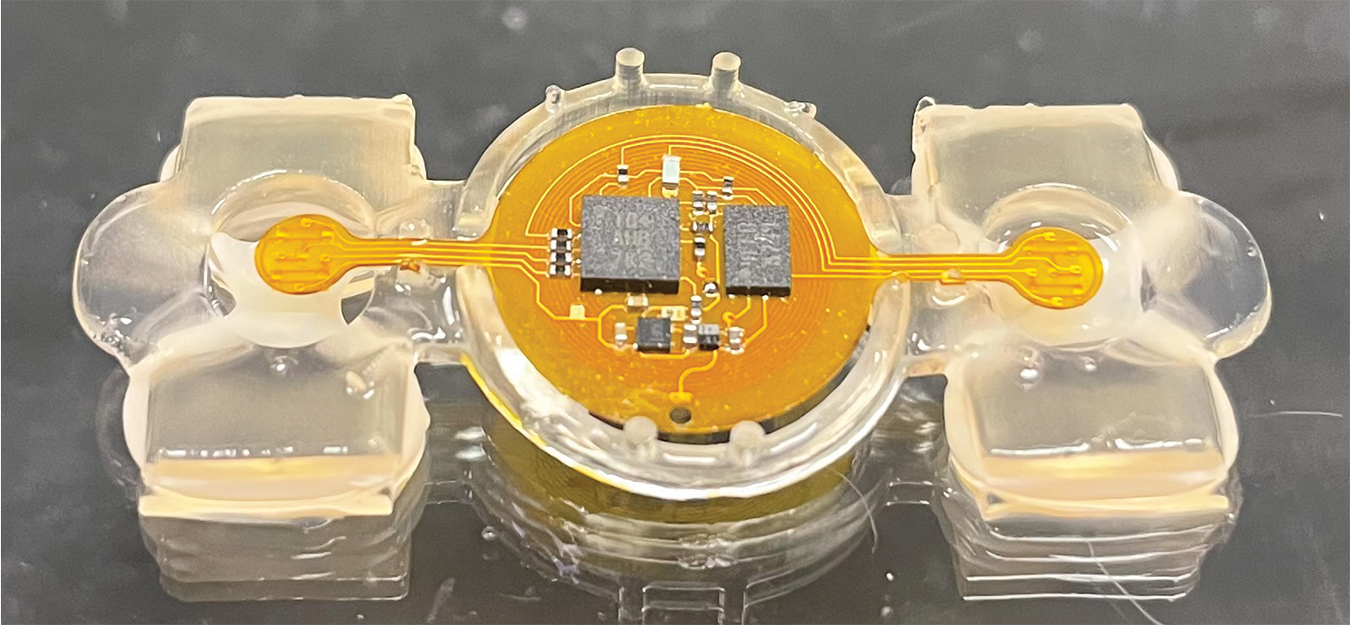

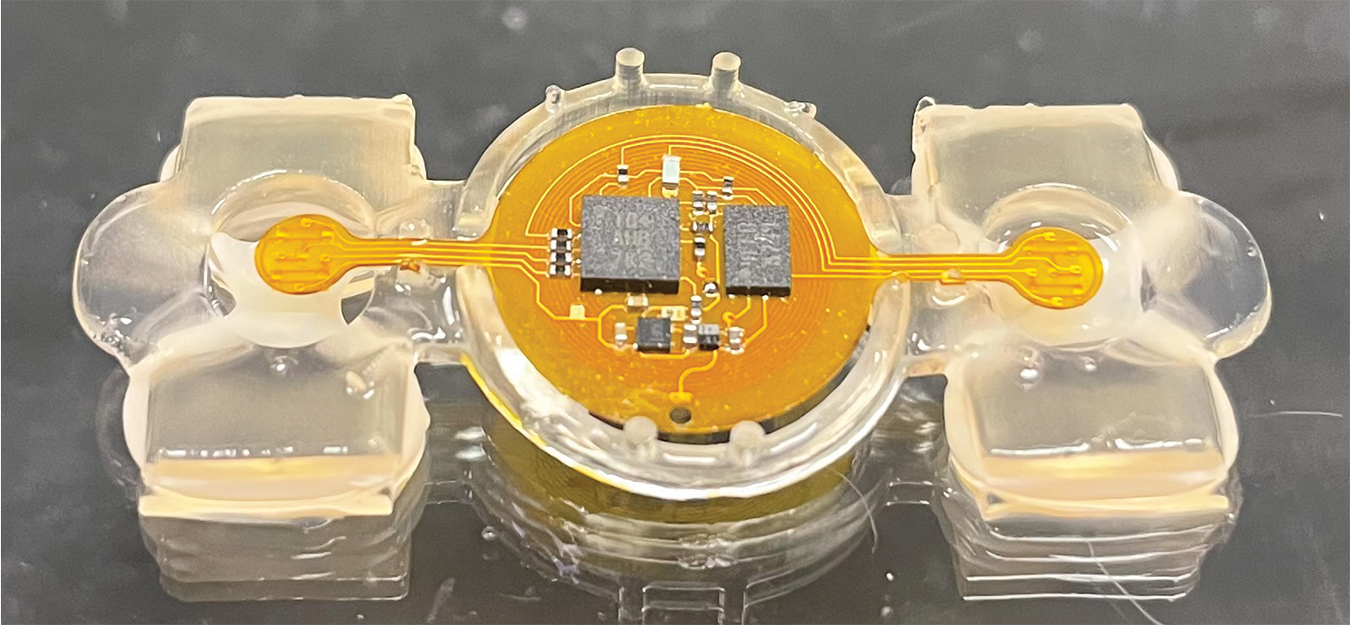

To give biobots the freedom of movement needed for practical applications, researchers set out to eliminate bulky batteries and tethering wires. The eBiobots use receiver coils to collect power and provide a regulated output voltage to power micro LEDs, says Zhengwei, co-first author and assistant professor of biomedical engineering at the University of Houston. Li said.

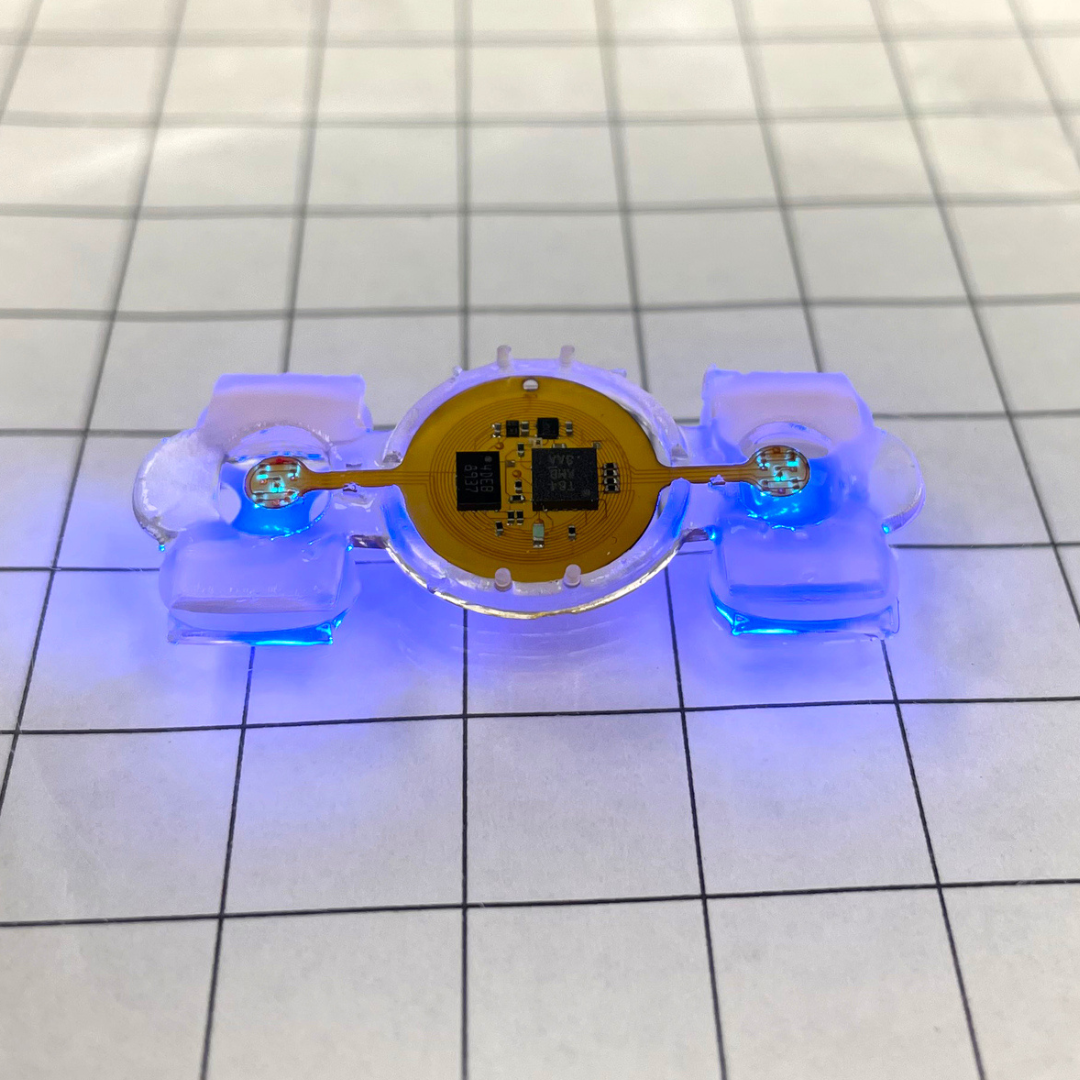

Researchers can send the eBiobot a wireless signal that pulses an LED. The LEDs stimulate light-sensitive artificial muscles to contract, moving polymer legs to make the machine “walk.” The micro LEDs are targeted to activate specific parts of the muscle, directing the eBiobot in the desired direction.watch video in Youtube.

Researchers used computational modeling to optimize the eBiobot’s design and component integration for robustness, speed, and operability.Professor of Mechanical Science and Engineering, Illinois Mattia Gazzola Led the simulation and design of the eBiobot. The iterative design and additive 3D printing of the scaffold enabled a rapid cycle of experimentation and performance improvement, said Gazzola and his co-first author Xiaotian Zhang, a postdoctoral researcher in Gazzola’s lab. I’m here.

The eBiobot is the first wireless bio-hybrid machine that combines living tissue, microelectronics and 3D printed soft polymers.Image courtesy of Kim Young-deok

This design allows for the future integration of additional microelectronics, such as chemical and biological sensors, or 3D-printed scaffolding parts for functions such as pushing or transporting anything the biobot encounters. co-author Youngdeok Kim said. A graduate student in Illinois.

By integrating electronic sensors and biological neurons, the eBiobots could sense and respond to environmental toxins, disease biomarkers, and more, researchers say.

“By developing the first-ever hybrid bioelectronic robot, we open the door to new paradigms of healthcare innovation applications such as in-situ biopsy and analysis, minimally invasive surgery, and even cancer detection in the human body.” said Li. Said.

The National Science Foundation and the National Institutes of Health supported this work.